Hi, I recently applied 1.25 gearbox in 1.7 puma engine, I've read a few threads but didn't find my answer, the reverse switches are diferent.

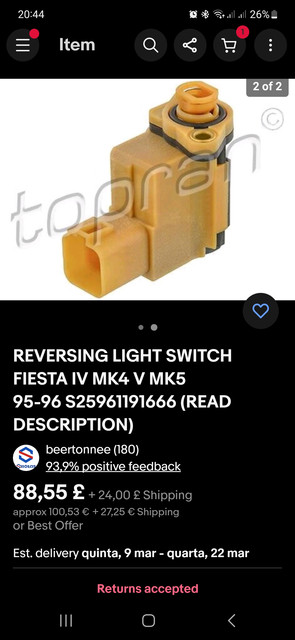

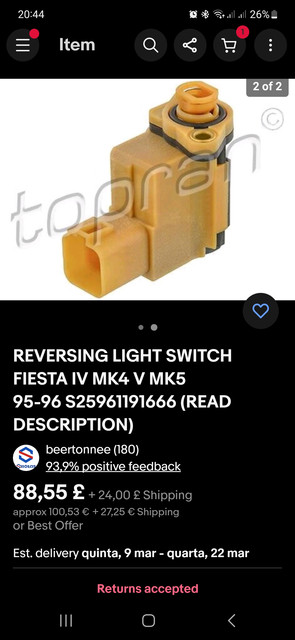

My 1.25 gearbox from a 96 Fiesta has this reverse switch:

And the puma loom has the triangular fitting switch that goes into this:

How do I make the conversion to make it work?

Thank you

My 1.25 gearbox from a 96 Fiesta has this reverse switch:

And the puma loom has the triangular fitting switch that goes into this:

How do I make the conversion to make it work?

Thank you