So, a smallish update. I am sorry that progress is very slow, but I am just so busy lately and by the time I get home it is pitch dark and cold and since I have no heating in my mancave the things are not progressing as I would like them to!

So I am now focusing mainly on research and planning...

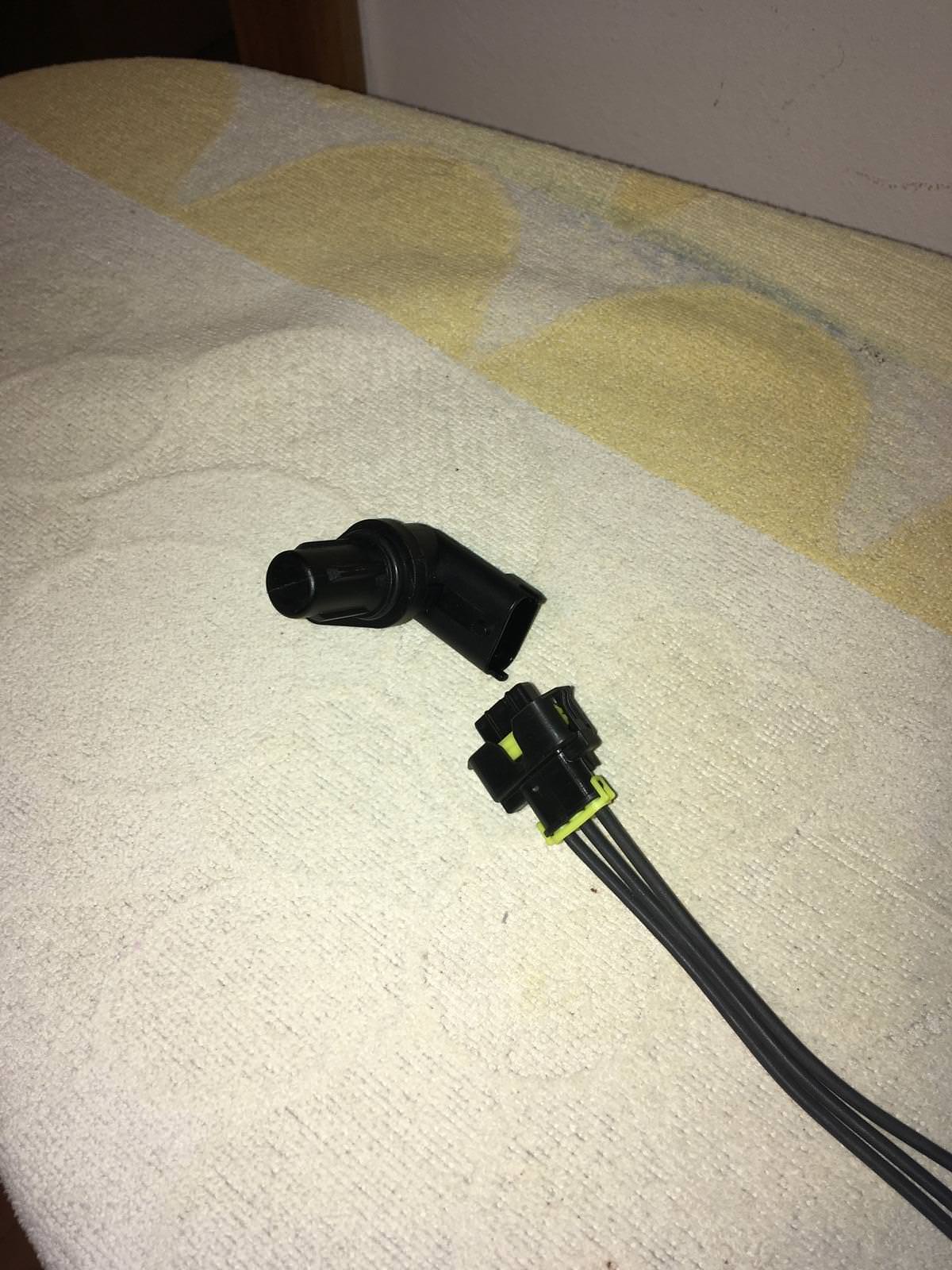

Anyway, this is the setup I am going to use (hopefully) as my VSS replacement.

This is the camshaft position sensor from a Hyundai i30/i20. Nothing fancy about it, just happened to have access to the connector and pigtail for it, hence the choice. When you come down to it, all are the same, i.e. do the same thing. As said, all the sensors are doing the same thing, the only differences among them is the packaging. There are som other candidates if this one turns out to be unsuitable.This one is Hall type, what is denoted by 3 wires.

One wire is +, the other is ground and the third one is signal. It works both on 12V (as intended in Hyundai, most probably to be more resilient to distortions) and 5V. When sensor is in proximity of a ferrous metal it opens up the signal and sends the puls of 12V or 5V (depending on what is connected to).

There are two wire sensors which are VR (inductive) and they produce sinusoidal voltage that needs processing to be turned into voltage peaks needed by PCM, instrument cluster and PS pump. They need certain speed of rotation for the rings to be of use. The same type is used in ABS in puma and as you know it doesn't work below 5-6 kph. Hence I opted for Hall type.

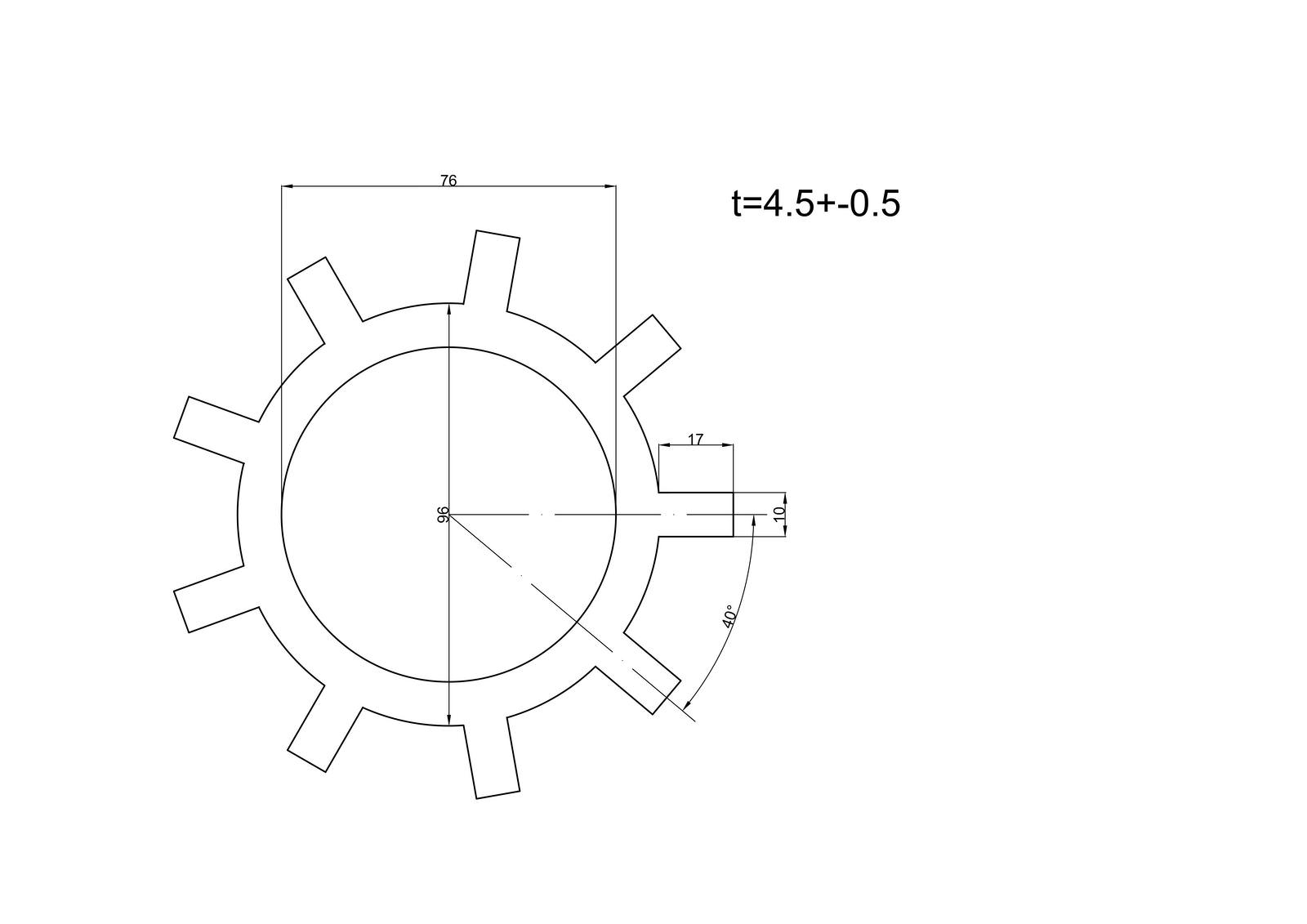

I will have this tone ring laser cut from 4.5 - 5 mm thick steel plate (not stainless, it has to be magnetic)

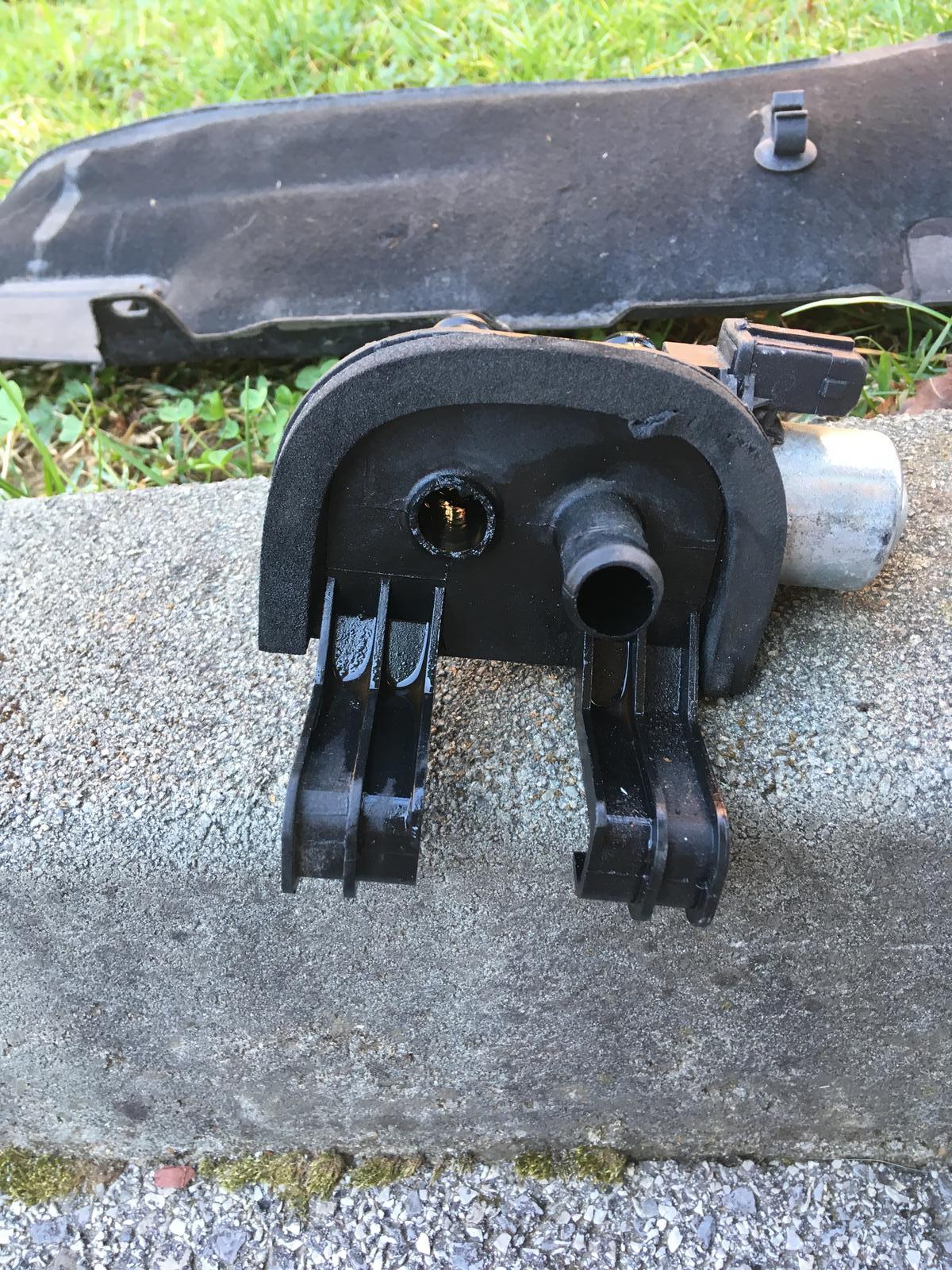

It has 9 teeth as that is what my instrument cluster needs per wheel revolution to operate. The Toyota PS pump needs 4.5 pulses per wheel revolution so that signal would need scaling down by 50%. The idea is to have it installed to the rear hub. Might make additional 3 holes for attaching it to the hub by 3 bolts to secure it properly. There will some be needed some bracket for the sensor, but will cross that bridge when come to it.

The other option would be to use another ABS sensor at rear already existing tone rings (you can just make another opening for it on the other side of the hub) but that one has 44 teeth so would need some serious scaling down (dividing by factor of 4.89 for IC and by 9.78 for PS pump) and, as already explanined, wouldn't operate below 5-6 kph, but no need for machining the hub, fabricating the bracket etc...

So that's it for the moment. When there is some development, will post it