Hi everybody,

After some thinking and encouraged by my good friend Pumanoob, I have decided to post my journey with my puma so far. JASAPP? What it stands for? Just Another Sub Average Puma Project. Having seen miracles performed by some of the members here, my effort is waaaaaay off that standard and abilities hence the Jasapp!

Anyway, I went to buy my puma in Germany. I wanted a good example and went to collect in Bonn. That is just about 1000 km in one direction. It was (and still is) futura model, in apperance very similar to millenium edition as far as the interior goes (recaro seats, full leather interior). The colour is moondust silver.

So, after a nice drive to Bonn and back, here she was in my carport

Standard car with F1 wheels. When I collected it was deep winter and going from Germany meant I7d need to pass thorugh Alps so I bought winter tyres before I went home with it; no way I would have passed through Alps without them!

Two weeks later, I had an accident: a deer jumped into me on a local road!

The end result:

As the car was going to be repaired to get rid of the rust, not to much harm, except I had to buy a new headlamp…

Soon I prepped the car for the bodyshop.

The worst of the rust was in VIN area. Went on to see my MOT tester to get advice on that. He said nothing to worry, just cut it out, repair the area beneath it and put it on top. He saw the car, the numbers are visible, no problems there! Phew, one worry less!

The car at body shop. The usual rusty rear end was replaced with zinc coated 1.2 mm thick steel. Also, did it without the bended section inside which is causing the rust in the first place!

Both sides done, the underbody as well, and sealed and sent off to paintshop. The car prepared for the spray job

And the area hit by deer repaired

The car after respray. I did respray everything except the roof. Thought of doing that as well, but since I have heated windscreen, and the guy doing the spray job said there was 10% possibility it would crack on taking down so decided against it. It is expensive as hell…

EDIT: started reposting with images now hosted by imgur. Won't be held ransom by photobucket!

After some thinking and encouraged by my good friend Pumanoob, I have decided to post my journey with my puma so far. JASAPP? What it stands for? Just Another Sub Average Puma Project. Having seen miracles performed by some of the members here, my effort is waaaaaay off that standard and abilities hence the Jasapp!

Anyway, I went to buy my puma in Germany. I wanted a good example and went to collect in Bonn. That is just about 1000 km in one direction. It was (and still is) futura model, in apperance very similar to millenium edition as far as the interior goes (recaro seats, full leather interior). The colour is moondust silver.

So, after a nice drive to Bonn and back, here she was in my carport

Standard car with F1 wheels. When I collected it was deep winter and going from Germany meant I7d need to pass thorugh Alps so I bought winter tyres before I went home with it; no way I would have passed through Alps without them!

Two weeks later, I had an accident: a deer jumped into me on a local road!

The end result:

As the car was going to be repaired to get rid of the rust, not to much harm, except I had to buy a new headlamp…

Soon I prepped the car for the bodyshop.

The worst of the rust was in VIN area. Went on to see my MOT tester to get advice on that. He said nothing to worry, just cut it out, repair the area beneath it and put it on top. He saw the car, the numbers are visible, no problems there! Phew, one worry less!

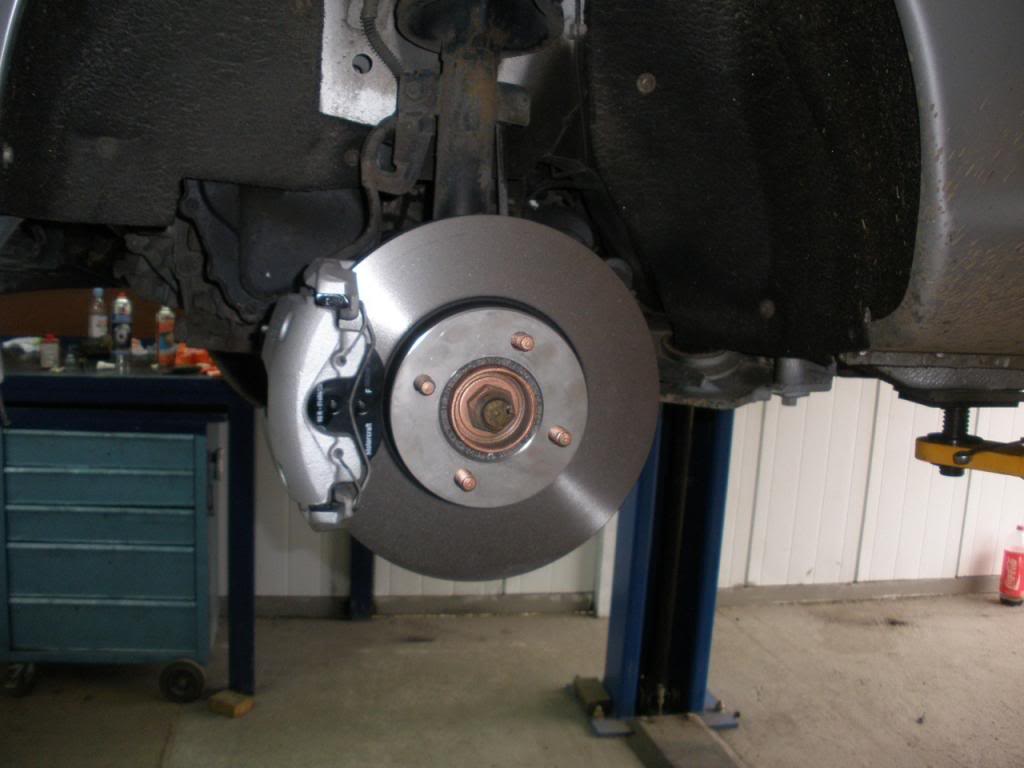

The car at body shop. The usual rusty rear end was replaced with zinc coated 1.2 mm thick steel. Also, did it without the bended section inside which is causing the rust in the first place!

Both sides done, the underbody as well, and sealed and sent off to paintshop. The car prepared for the spray job

And the area hit by deer repaired

The car after respray. I did respray everything except the roof. Thought of doing that as well, but since I have heated windscreen, and the guy doing the spray job said there was 10% possibility it would crack on taking down so decided against it. It is expensive as hell…

EDIT: started reposting with images now hosted by imgur. Won't be held ransom by photobucket!