Not much of an update lately as ive been skint last few months.

Few maintenance related items!

First of all the shocking roads in stoke have slowly destroyed my suspension!

Started to get a bit of a rattle so had a look underneath:

The bolt had ripped right out the chassis screwing the thread!!! Had to stengthen it and cut a new thread. Also added a captive nut inside the chassis as well. Now has about 4cm of good thread!

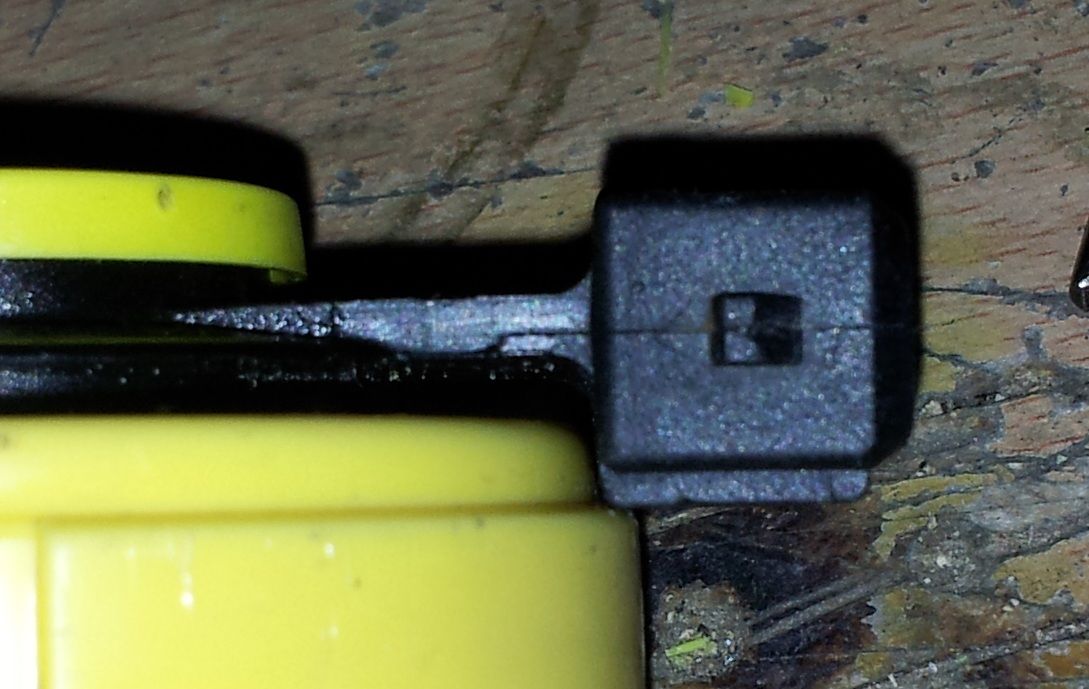

Also had a CV joint split on me:

All sorted now though. Just hope there is no excessive wear on the joint.

Not long after that i developed a new knocking sound that came from both sides in the end. On getting it on the ramp it was clear the bottom balljoints were shot on both sides.

Sounds pretty standard...... however as my car has custom TCA's it needed a bit of measurement to find out which ball joint had been used. It turns out standard puma ball joints which is useful for a change with my car - something easy to get and cheap!!

However, take off the old balljoint and you can see the very special bodging that has gone into the old ball joint!

This is how it looks compared to a new one:

The other one was similarly bodged but interestingly from a different manufacturer so in the bodging process he seems to have clearly just used two random old ball joints that were lying around rather than new ones. Dont understand why when new ones cost £20 a pair, less to the trade. They were definitely old as they have worn out in less than 15000 miles.

Finally its nice to have a new known part back on the car!!

Ive also upgraded my "crash cam" as ive had it a few years now and technology has moved on. Replaced it with a chinese special. for £20 seems good value and records in 720p which is more than adequate for my needs and is a combined DVR unit with screen. Its been tested for a few months now and seems reliable so has replaced my old system.

Wasnt perfectly happy with the mount as it sat too far back for me to hide the camera in front of the mirror. Not really a design flaw as such just that im pedantic over some things and i dont want the camera to interfere with my forward vision so wanted it mounted hidden by the rearview mirror when looking from the drivers position.

So the solution was to fabricate a simple adaptor out of carbon fibre to move the camera forward.

I over engineered it a bit i think as its stiffer than any other part of the mounting by a long way!!