Last week I went to see my engine..

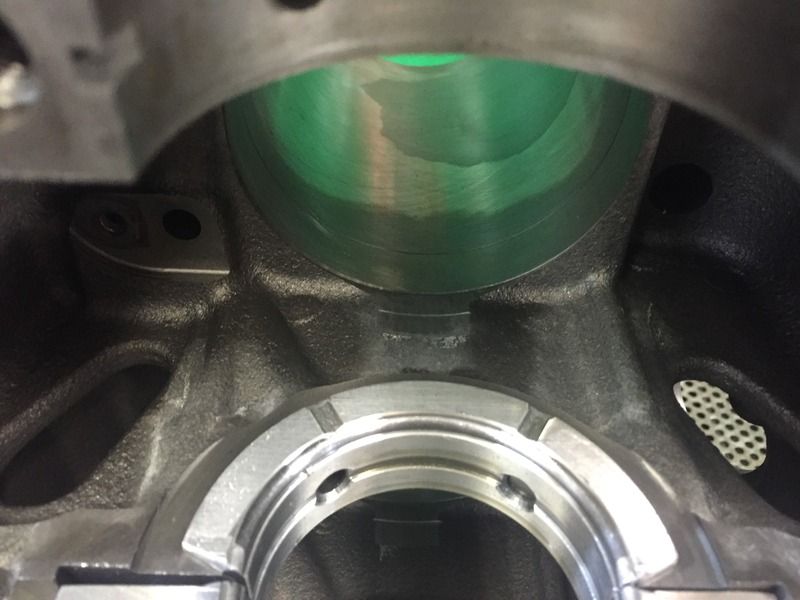

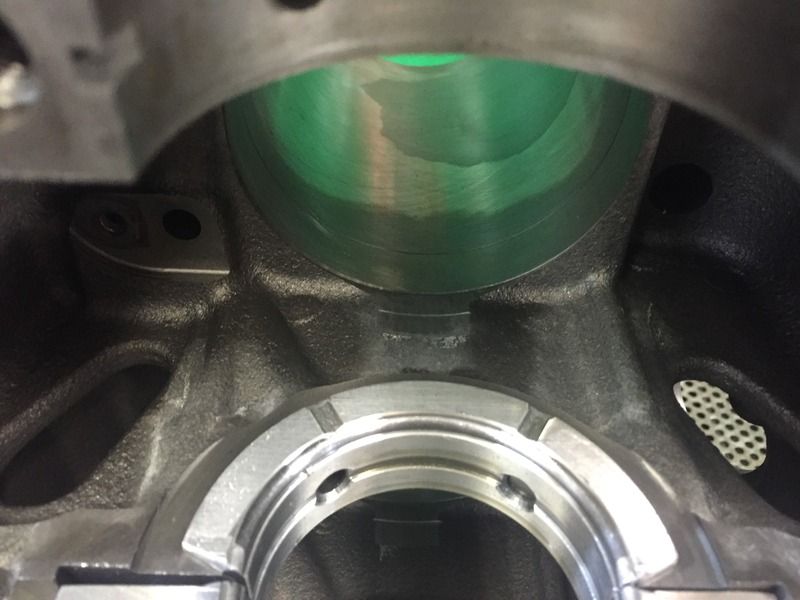

Here is how they modified the block to make a 360 degree thrust washer face. Simply, they have machined the cap to accept another journal bearing with built in thrust washer, as it is in the top. Have no idea why the engine wasn't designed like this in the first place. Still I think it's come out well

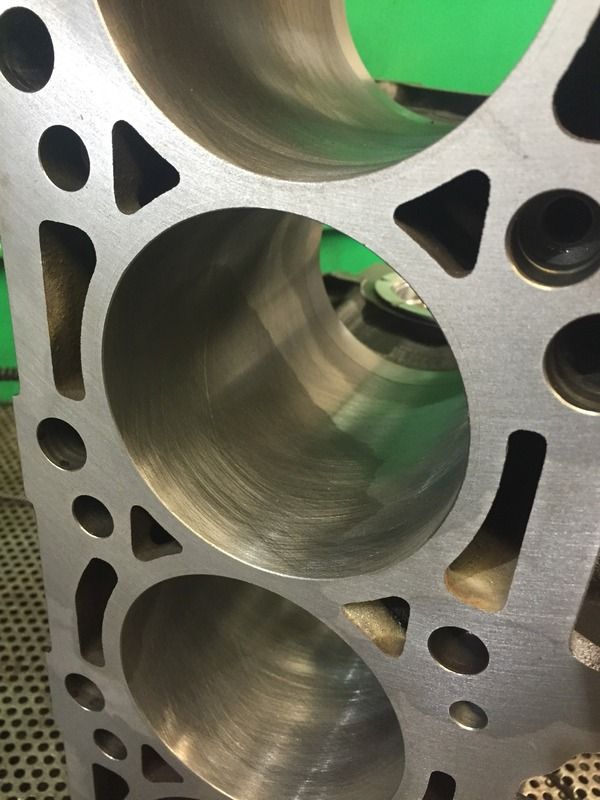

View of the bottom of the steel liners.. you can just about see the line to where the liner has bottomed out in the block. Sorry about the green reflection, the block was sitting in the parts washer.

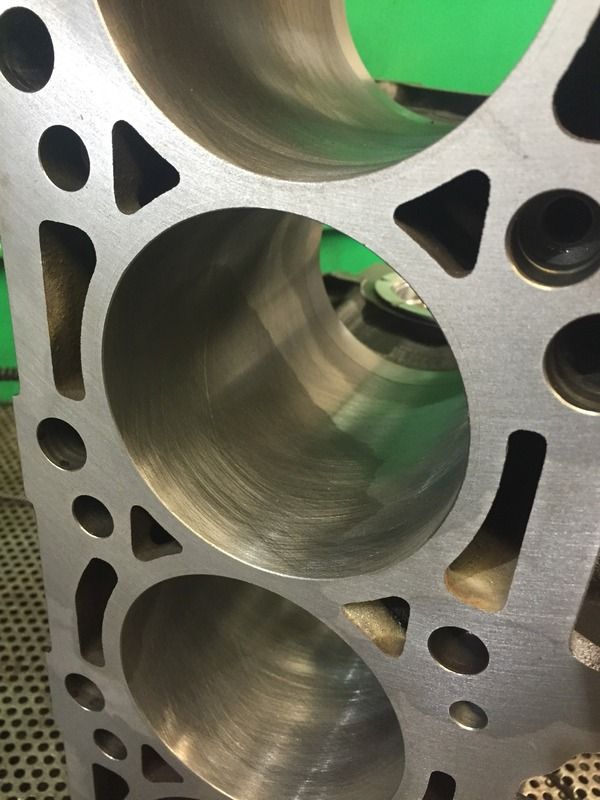

Again, here you can just about see where the liners are.

Flywheel got lightened. Though I have asked about skimming it since I am bolting up a new clutch.

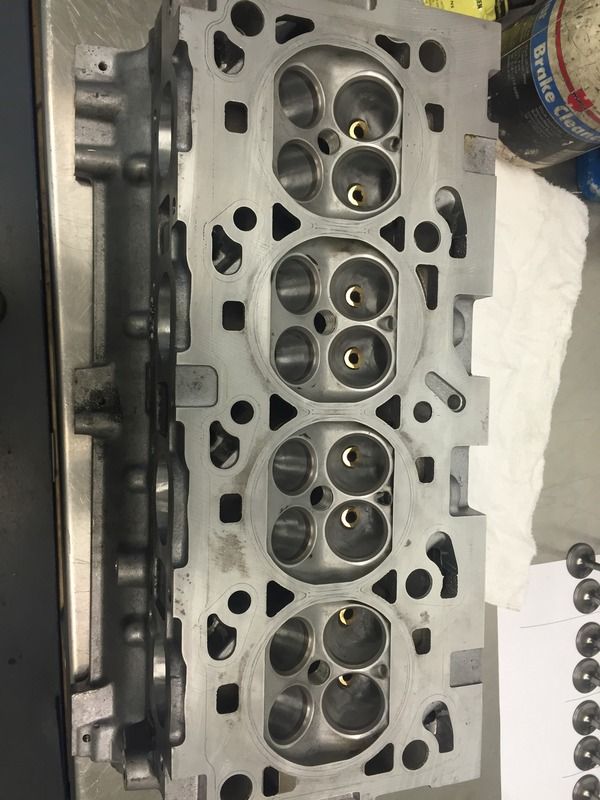

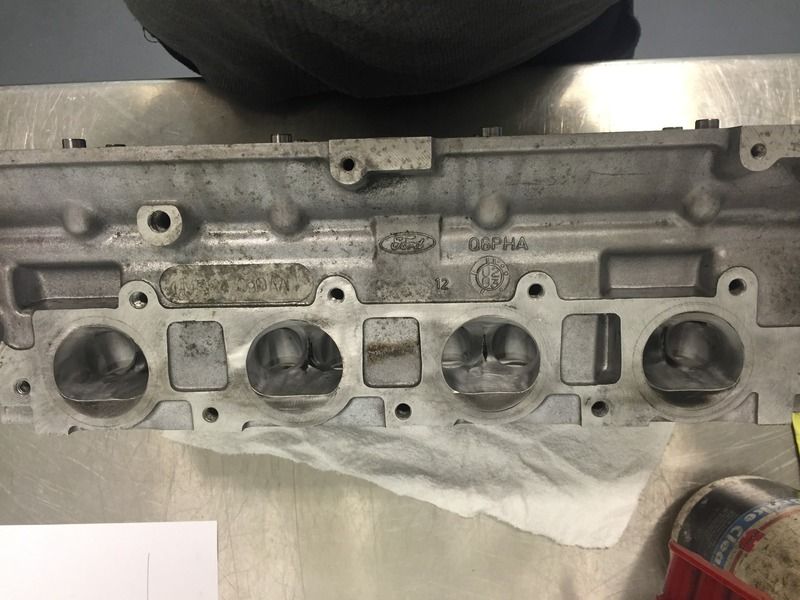

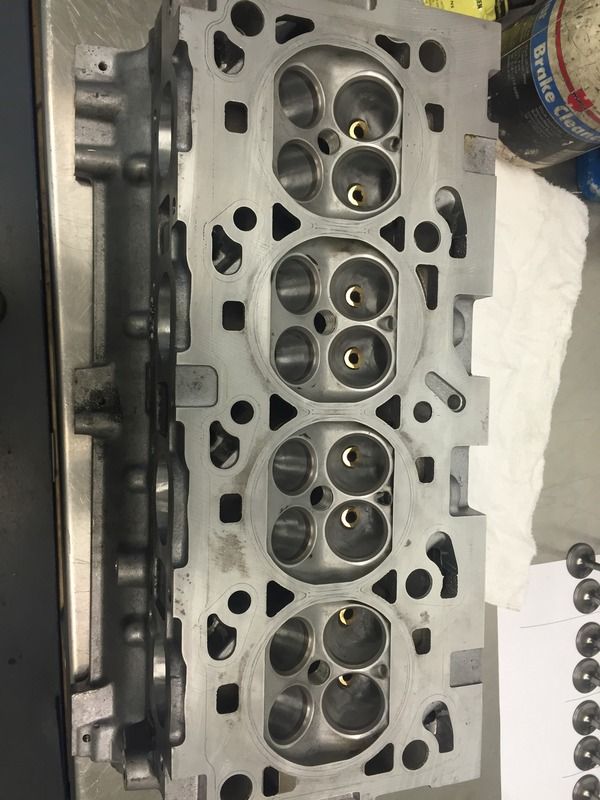

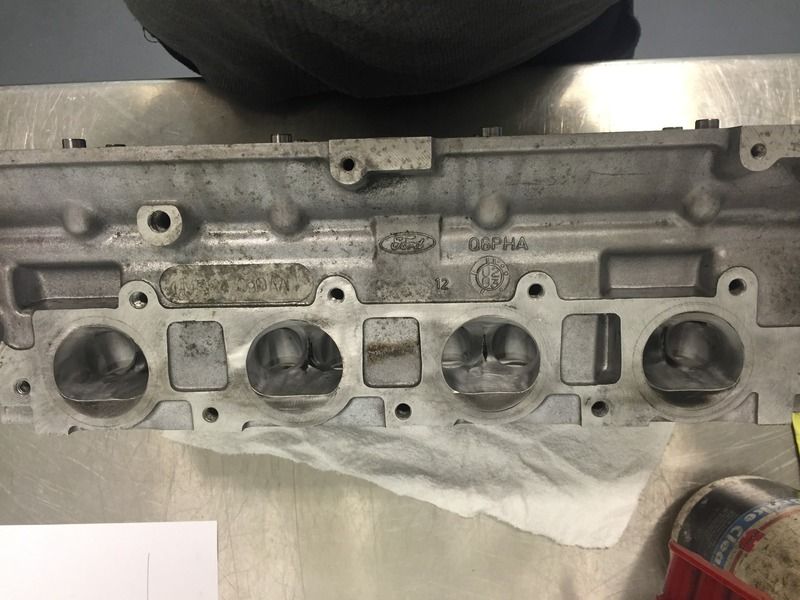

Head with valve guides cut back.

They ported and polished the exhaust ports massively by opening them up to the gasket line.

Existing PEC steel rods and Cosworth pistons to be re-used. They have been measured and checked.

Farndon Steel Crankshaft.. this is lovely

The engine was diarised to be built Wednesday/Thursday just gone, but haven't heard anything. Either they are waiting for me to get hold of the steel oil pump gears that I'm waiting for, or they they weren't happy with the machining tolerances. They are very particular!