RoadWarrior

Member

Hi all, as the title suggests my camshaft sensor is out 180 degrees.

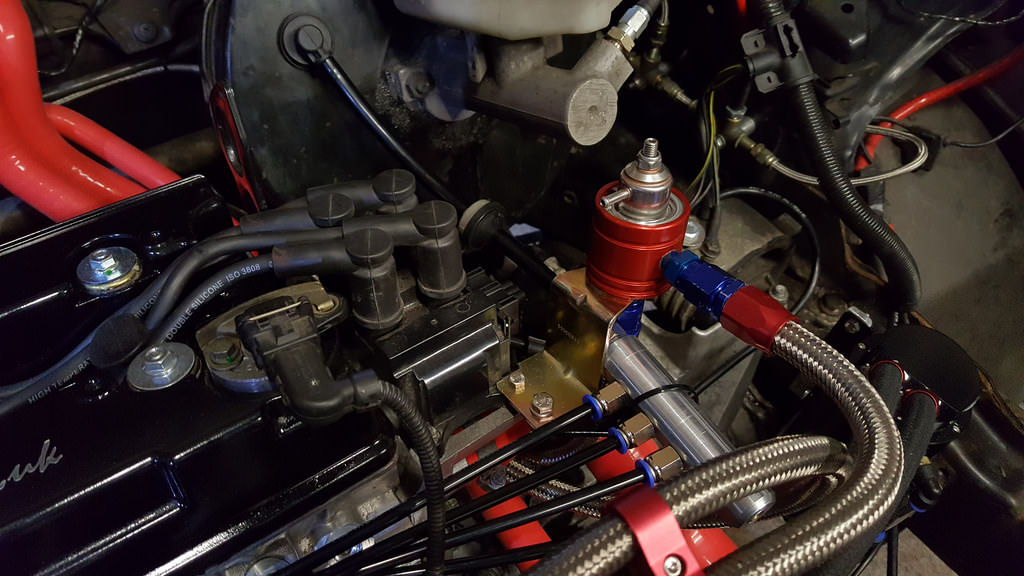

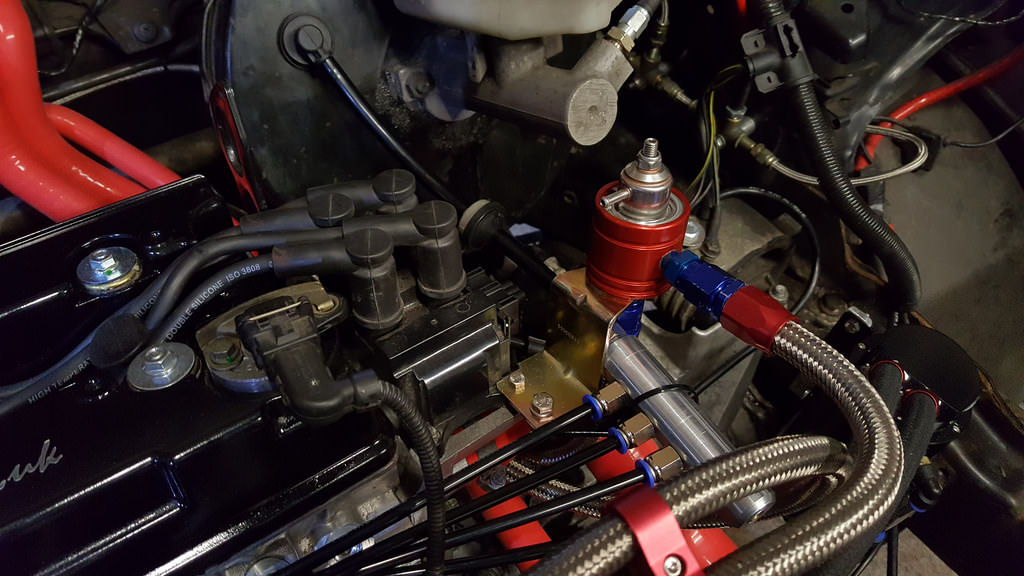

I put mine in the block and put the bolt through it, looking through puma projects the other day, I noticed it has a metal clip holding it the other way around?

(Image is a project off the internet note the metal clip around the camshaft sensor through the hole.)

The camshaft sensor is to the left near the coilpack, leaving the clip out and putting the bolt in (180 degrees the other way) shouldn't make it not idle and throw timing codes up, should it?

Will it need putting the correct way around?

I put mine in the block and put the bolt through it, looking through puma projects the other day, I noticed it has a metal clip holding it the other way around?

(Image is a project off the internet note the metal clip around the camshaft sensor through the hole.)

The camshaft sensor is to the left near the coilpack, leaving the clip out and putting the bolt in (180 degrees the other way) shouldn't make it not idle and throw timing codes up, should it?

Will it need putting the correct way around?