richard_rip

Member

- Joined

- Dec 20, 2016

- Messages

- 78

Hi. I thought some of you might be interested to see the work I'm carrying out of number 219.

We bought her in September 2015 off a chap in London and it had 140k on the clock, he'd had the arches redone and the wheels refurbed but mechanically it had quite a few bits wrong.

This is not a complete list of problems

Clutch was slipping

Accelerator pedal wasn't right

Idle was poor

Leaking a bit of water from somewhere

Kangaroo'd when you accelerated

Indicator stalk didn't work

Passenger window didn't work

The idea was to have this as a weekend/summer car and give me a little project. I've always worked on cars and earlier that year I'd rebuilt the head on a Renaultsport Clio 197 which isn't the easiest of tasks but I really enjoyed it. I'm a precision engineer by trade so I'm a bit of a perfectionist and the idea of a car needing a lot of TLC really appealed to me.

A couple of weeks after we collected her

I started easy, changed the window regulator, picked up a new unit for the indicator stalks, and new fuel sender unit. The sender unit fixed the kangarooing but it turns out the wires on the fuel gauge were the wrong way round so it reads backwards on the dash, which I kinda like so haven't changed it yet haha.

After a few months of owner her the small water leak had become a haemorrhage, turns out the head gasket was shot as well. I decided I'd do a full and proper job on it by rebuilding the entire engine so I put it under cover until better weather, not to mention the fact we decided to move house.

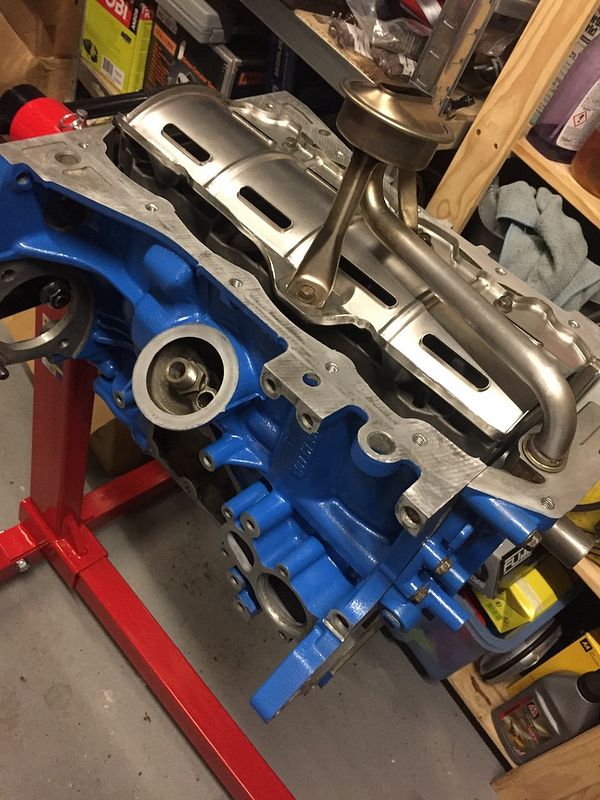

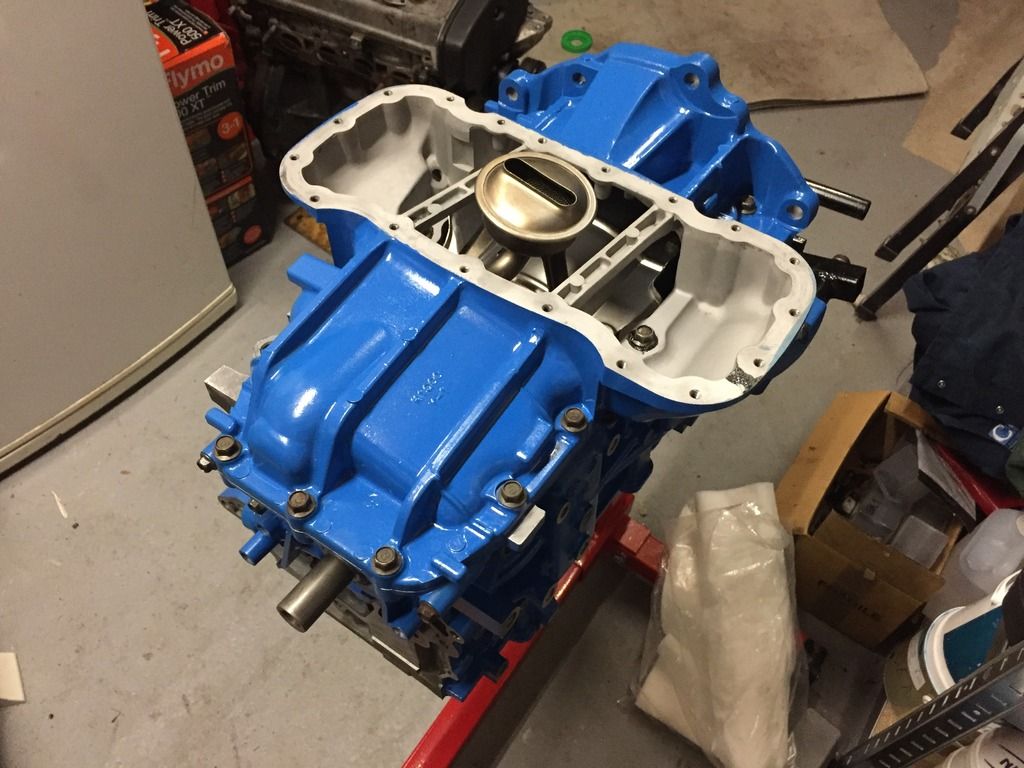

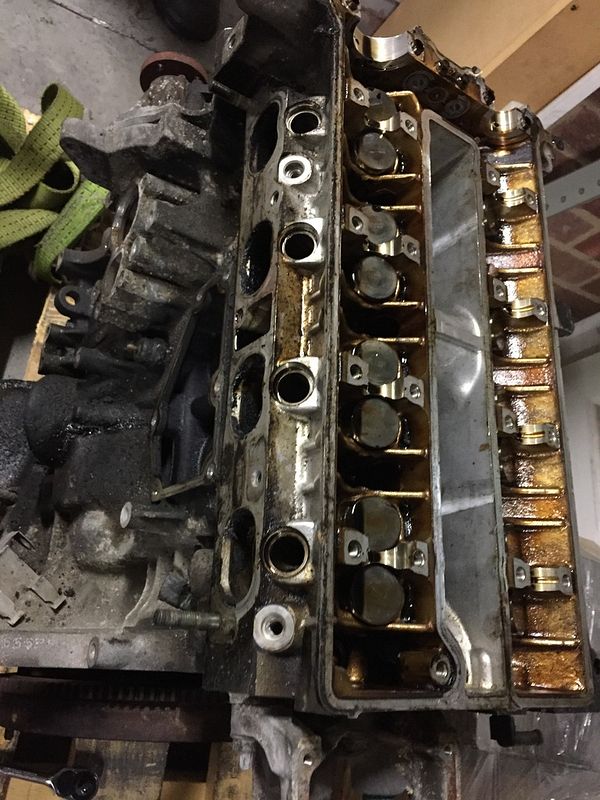

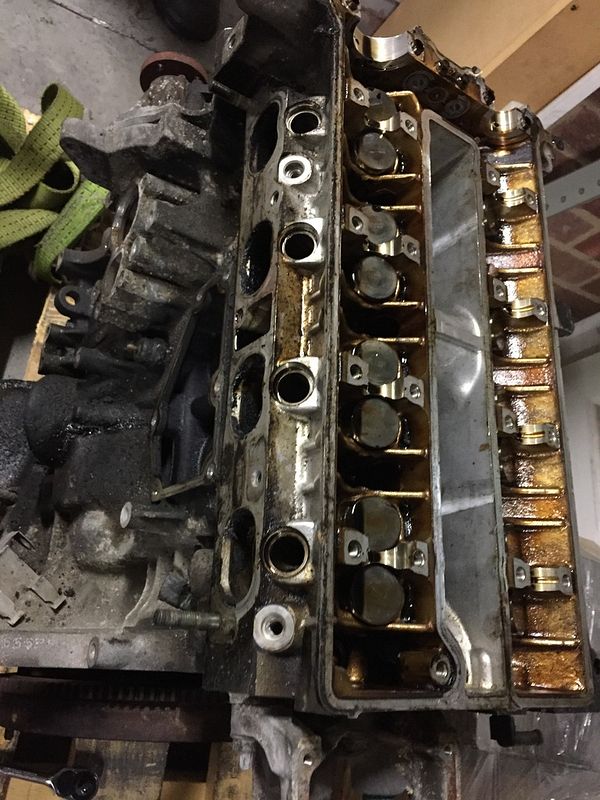

With the original engine having done 140k miles I was worried the bores would need recoating/honing so I decided to "practice" on a lower mileage engine off eBay. For £150 I went and collected a standard 1.7 unit with 78k miles on the clock and the plan was to the FRP bits in it from the current one. It was a little grubby

The first job was to get everything clean again and I decided to paint the engine a similar colour to the brake callipers, I know it's not to everyones taste but I wanted to give it a try and this was the engine to try it one.

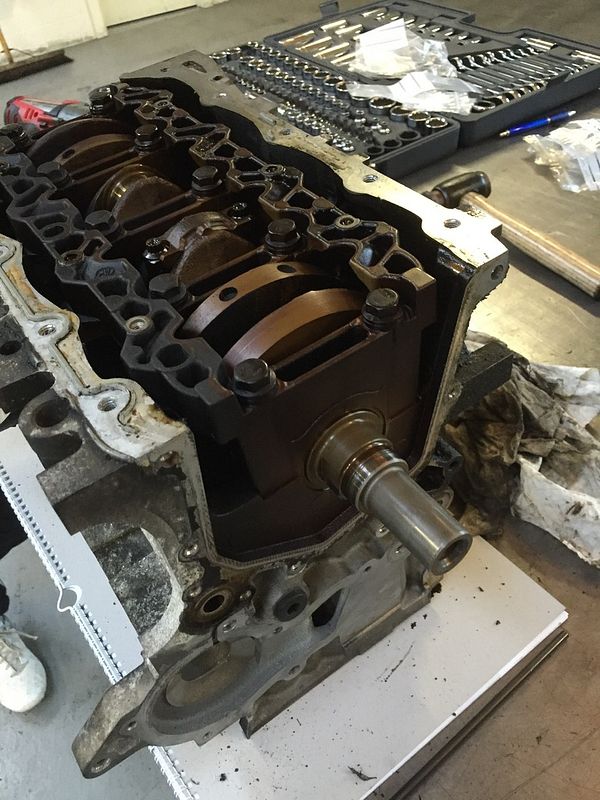

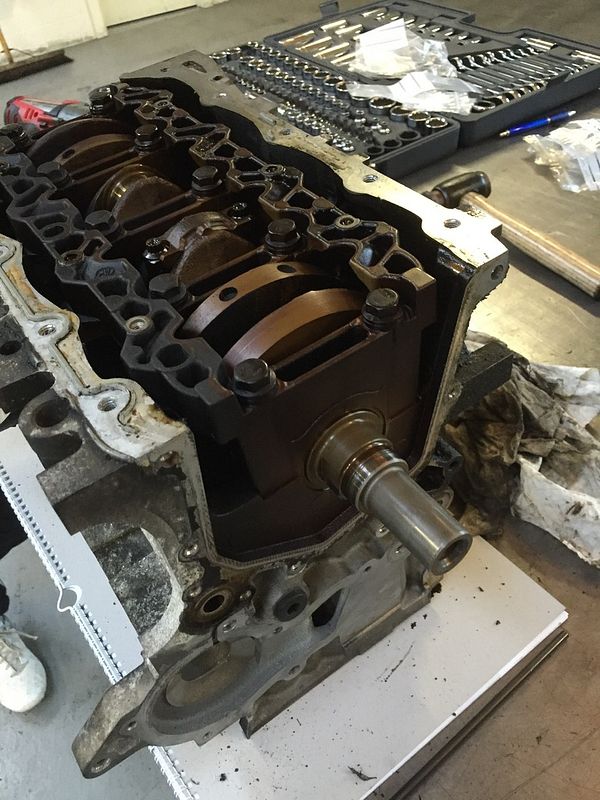

I took the block and head into work to test the bores for diameter and taper, both were within tolerance to Ford spec. I also checked the contact faces that the head gasket sits between for flatness, both the block and head were flat within 0.03mm

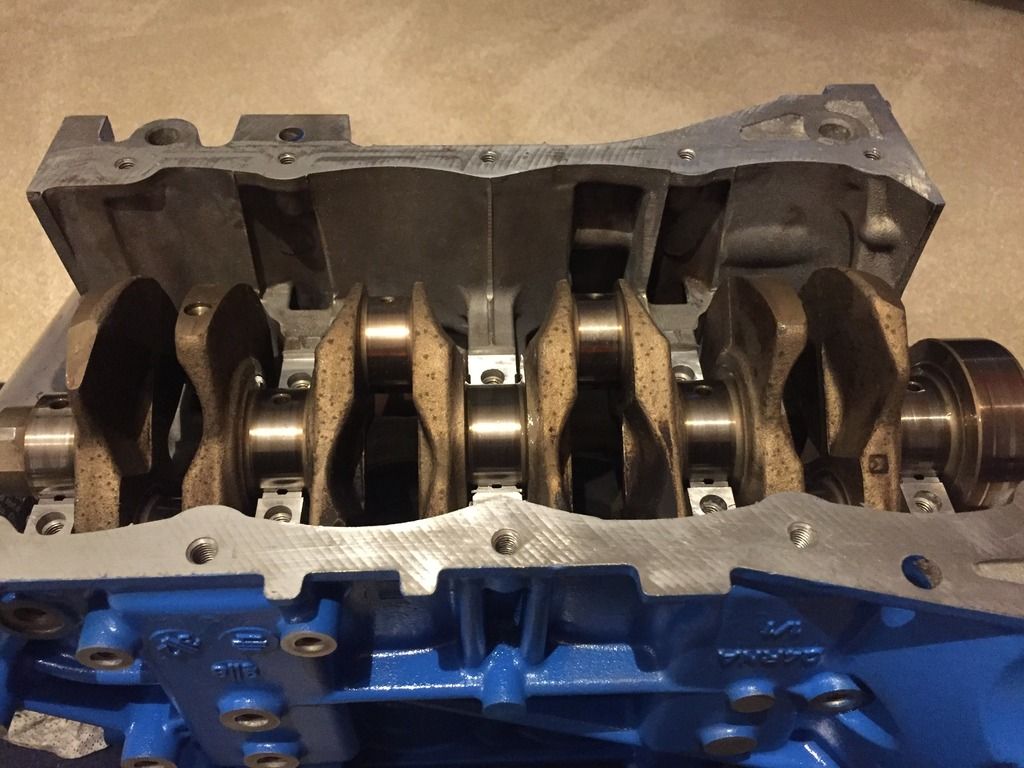

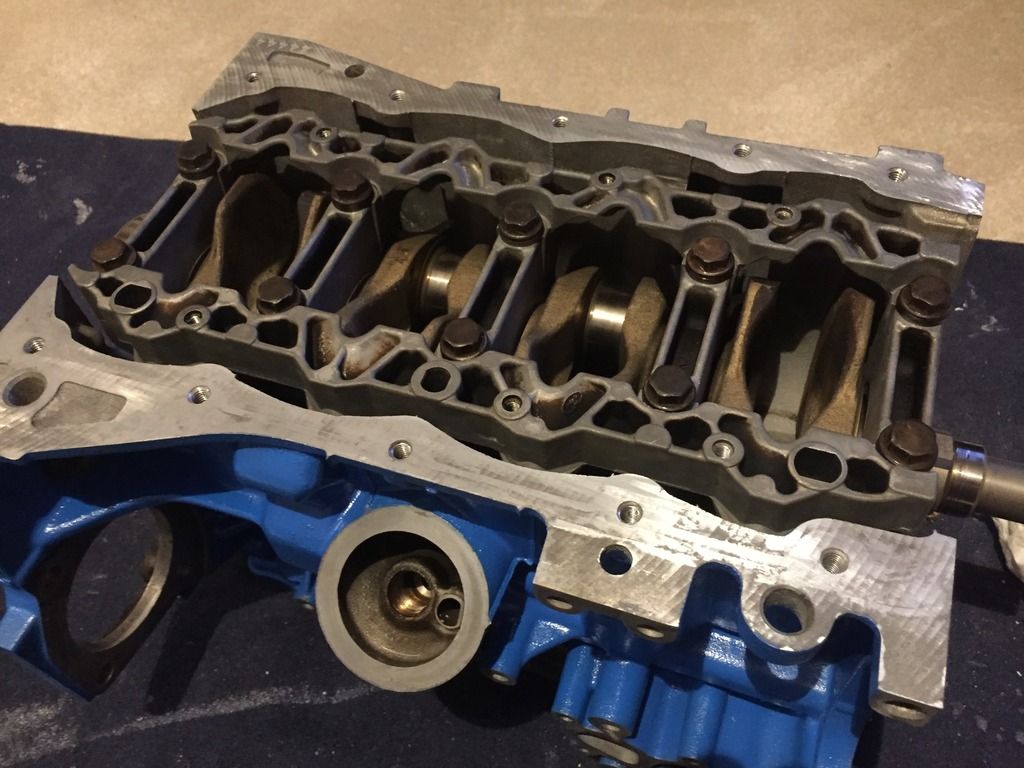

I measured the clearance on the big ends and mains and it was right on the limit of spec so I decided to change them all. The mains were easy to get but the big ends were a different matter. After much searching, a few sets delivered that didn't fit, and a bit of help from some on PumaPeople, I found out that big ends from a Mitsubishi engine were the correct size. The only problem was that the location pip was on the wrong side so another trip to work was required to.

I set the journals and rods up on a milling machine, they weren't as hard as I was expecting

The new shells after I'd got the size and position just right

We bought her in September 2015 off a chap in London and it had 140k on the clock, he'd had the arches redone and the wheels refurbed but mechanically it had quite a few bits wrong.

This is not a complete list of problems

Clutch was slipping

Accelerator pedal wasn't right

Idle was poor

Leaking a bit of water from somewhere

Kangaroo'd when you accelerated

Indicator stalk didn't work

Passenger window didn't work

The idea was to have this as a weekend/summer car and give me a little project. I've always worked on cars and earlier that year I'd rebuilt the head on a Renaultsport Clio 197 which isn't the easiest of tasks but I really enjoyed it. I'm a precision engineer by trade so I'm a bit of a perfectionist and the idea of a car needing a lot of TLC really appealed to me.

A couple of weeks after we collected her

I started easy, changed the window regulator, picked up a new unit for the indicator stalks, and new fuel sender unit. The sender unit fixed the kangarooing but it turns out the wires on the fuel gauge were the wrong way round so it reads backwards on the dash, which I kinda like so haven't changed it yet haha.

After a few months of owner her the small water leak had become a haemorrhage, turns out the head gasket was shot as well. I decided I'd do a full and proper job on it by rebuilding the entire engine so I put it under cover until better weather, not to mention the fact we decided to move house.

With the original engine having done 140k miles I was worried the bores would need recoating/honing so I decided to "practice" on a lower mileage engine off eBay. For £150 I went and collected a standard 1.7 unit with 78k miles on the clock and the plan was to the FRP bits in it from the current one. It was a little grubby

The first job was to get everything clean again and I decided to paint the engine a similar colour to the brake callipers, I know it's not to everyones taste but I wanted to give it a try and this was the engine to try it one.

I took the block and head into work to test the bores for diameter and taper, both were within tolerance to Ford spec. I also checked the contact faces that the head gasket sits between for flatness, both the block and head were flat within 0.03mm

I measured the clearance on the big ends and mains and it was right on the limit of spec so I decided to change them all. The mains were easy to get but the big ends were a different matter. After much searching, a few sets delivered that didn't fit, and a bit of help from some on PumaPeople, I found out that big ends from a Mitsubishi engine were the correct size. The only problem was that the location pip was on the wrong side so another trip to work was required to.

I set the journals and rods up on a milling machine, they weren't as hard as I was expecting

The new shells after I'd got the size and position just right