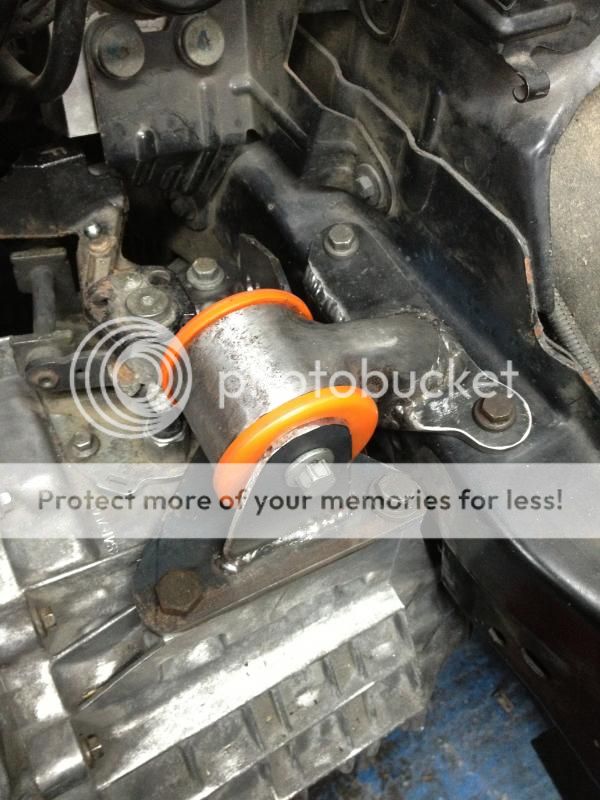

Then onto the rear stabilising mount. I wanted to use the standard puma mounting on the car, so I set about making something work from the gearbox to bring it to the right place as the focus one is further over towards the centre of the car.

After some manipulation with the grinder and flap disc!

Once the gearbox was in and mounted, I found that my ABS pump bracket needed to be modified to allow the weighted arm on the shift mechanism to swing round.

I then started on the cable shift and getting a route through. I should have removed the dashboard to do this really, but I managed without as to be quite frank I couldn't face taking it out, what with the loom attached and my gauge wiring fed through. Also cut out and plated the old rod shift hole, then put rivnuts in for the new gearstick.

FRS driveshafts, gearstick and cables

Then preparation..

Also, had to take a section from the subframe to allow cables through without too much stress and allow for a smooth gear change.. I think I might put a further plate in to add some strength.

This was painted on the reverse side before the section was welded in. I also managed to cut slots and tie together the thinner plate inside when I welded.

When the gearbox came out again I could trim and box back in the chassis leg:

Then the 'box came out and lots of tidying up and painting took place!

ABS pump bracket fitted back in

After a long thought I decided to paint the gearbox.. in a Ford colour of course

Also started work on my driveshafts.. thanks to Errol, I saved a lot of time and got some focus 2.0 shafts as I couldn't get the FRS ones to fit, the CV joints are huge! I managed to work out (after a long time!) that the nearside shaft was actually the exact length I needed for my offside shaft once the half shaft was in place. Spot of luck that saved me having one made! However, I did have to measure and get the nearside one made, which I got back this week, after some great expense - glad I only had to get one!

I also needed to modify the bracket to hold the half shaft. The FRS bracket is different to the 2.0 one as the FRS intermediate bearing is smaller as the oil drain from the breather ducks behind it. With some modification I could get the 2.0 one to work well..

Painted:

Along all these works I found some holes in my floor

same places each side too. Will and have cut most of them out and then Ill be welding in some good new metal.

Undersealed where I did the modifications for cable shift with 3m sealer to get the factory finish (although I sprayed a bit thick on this section). Thought I had a pic, but seems to have gone missing.

I have also moved my oil cooler and made mountings for this, but no pics yet. Will get some pics of gearbox fitted also. Nearly time to bolt all back together and weld up downpipe as I don't think my current one will fit..

Hopefully more pics and progress to follow!