It's been a while since I posted but plenty has happened to the car. The engine's back in and has done 500 miles, I did have a bit of an oil leak which I tracked down to the rocker cover but a new gasket and some sealant fixed that. Apart from that it's been running really well.

The old girls had new boot struts, CD player (old one went pop), dash clock (old one went pop).

After doing some digging regarding new front brake discs and pads I got a little concerned about the calipers, these Alcon 4 pots seem prone to corroding so I thought I'd strip them and see how they were.

Got them off the car

Getting the pipes off was a bit of an arse, and one of the calipers was tricky to split as a bolt had seized in

3 of the stainless plates came off well o one of the calipers, one had to be drill out at work

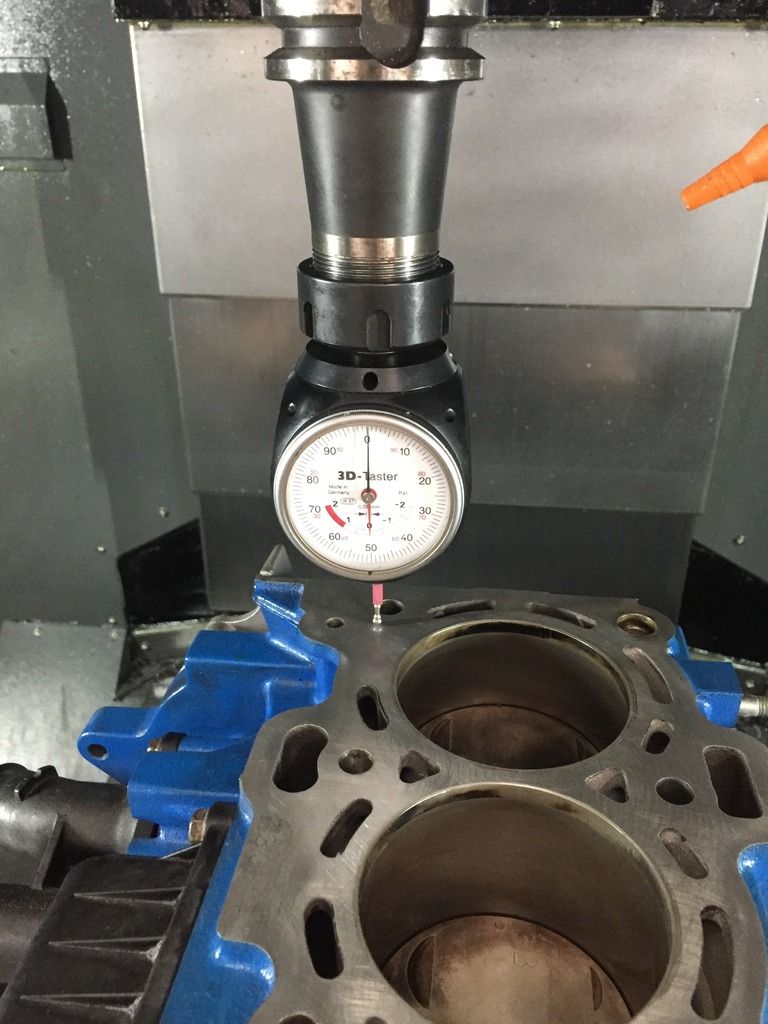

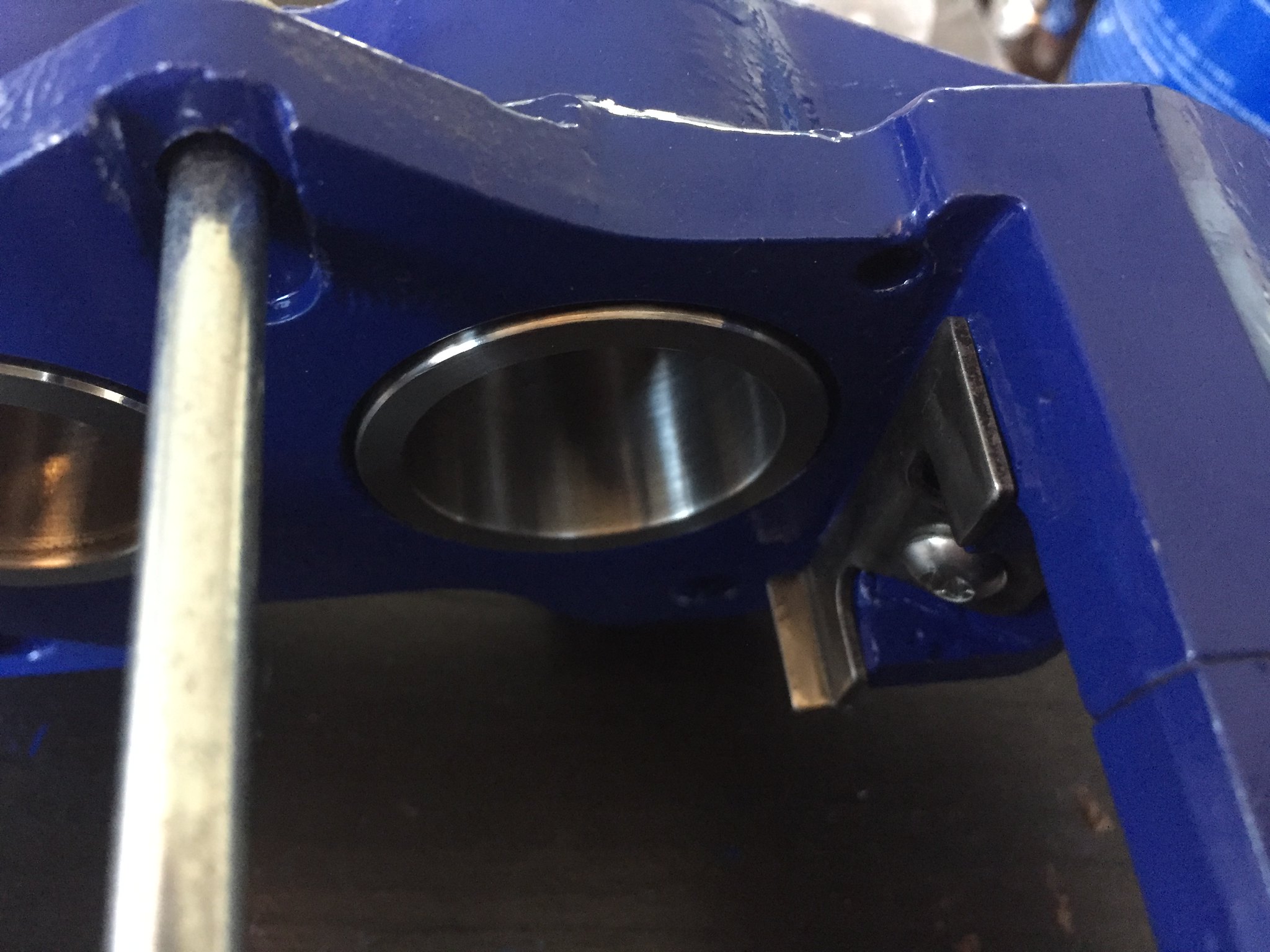

5 of the pistons were actually in really good condition, 3 were not so I ordered a length of 316 stainless through work and turned them on our CNC lathe

Once the plates were off I could see if there was any corrosion under them, I think I've been pretty fortunate as there wasn't much.

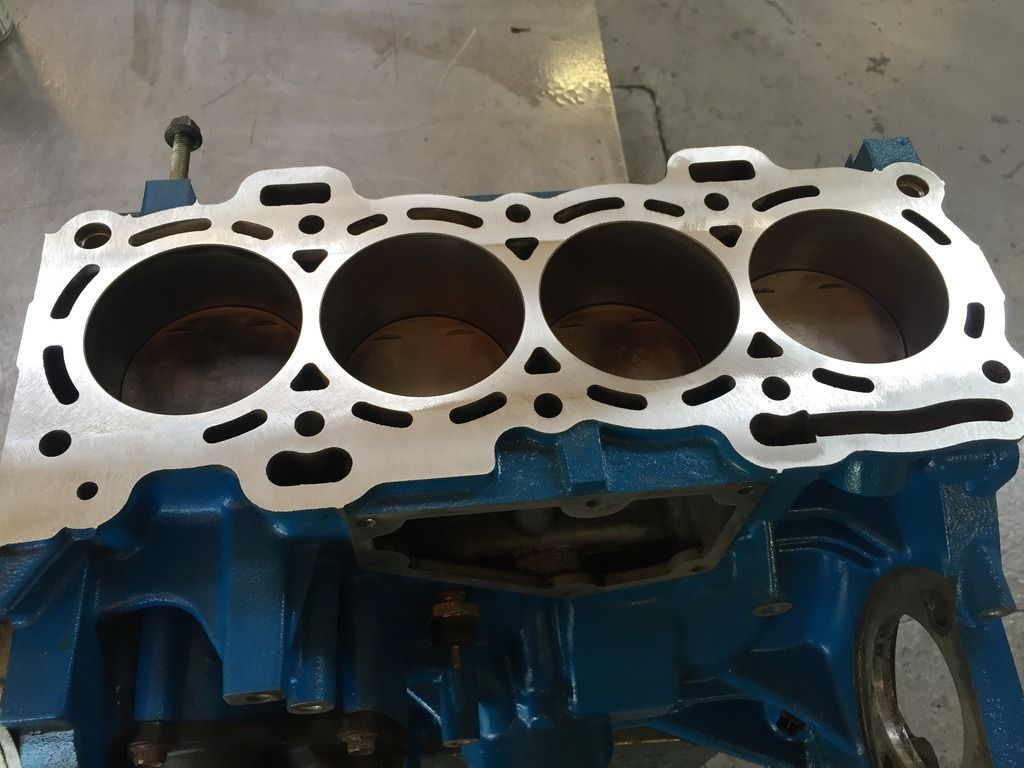

Next job was to remove the piston seals and get them sand blasted using a super light grit. Once that was done I got a few coats of caliper paint on them, the colour is slightly different to standard but I thought it's better than nothing

I spoke to Chris at Allison automotive and ordered new seals, bridge pipes and connectors. I also ordered new stainless bleed nipples and some zinc plated 12.9 high tensile bolts through work.

Everything that was sensible to salvage was, otherwise it was replaced, this is what they looked like rebuilt

And finally back on the car