Hi Barry,

Just got little how-to together for you!

This is the setup I am using. A small hp laptop with atom procesor running windows XP. OBDII scanner ELM327, here in USB version. I have also WiFi version, but USB is much better. More stable, faster and easier to setup what is probably of more improtance to you (no offence!).

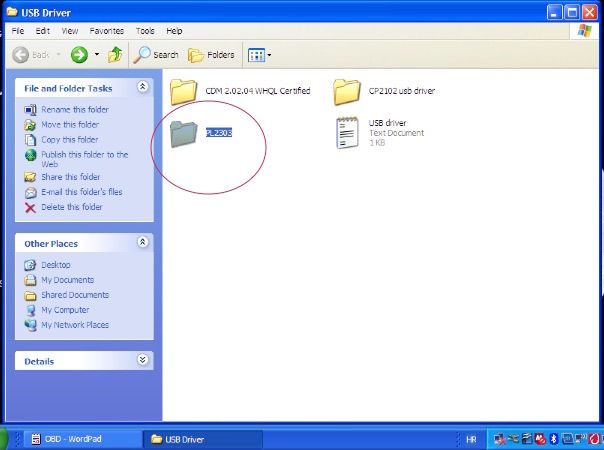

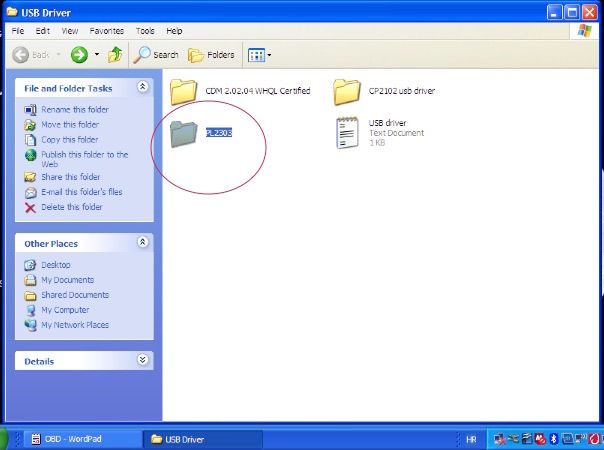

With scanner comes the small CD with the drivers needed for it to run on computer. Open the circled folder

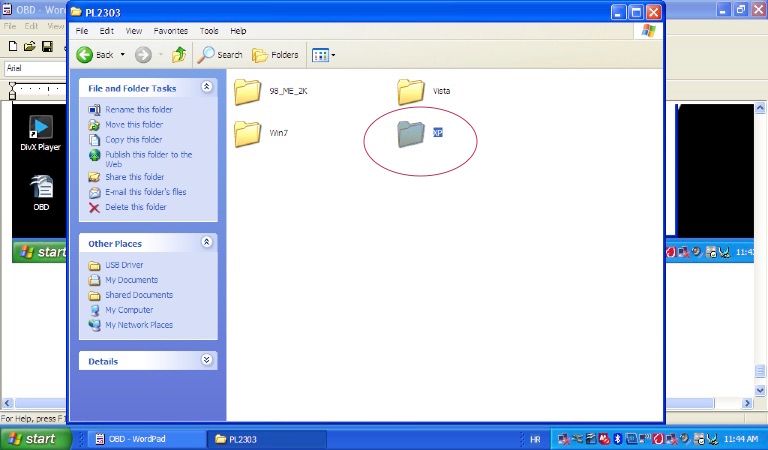

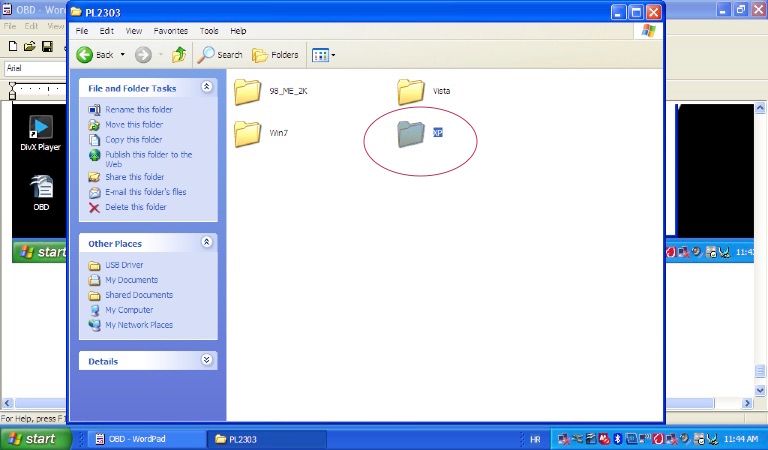

Click on the folder depicting your version of windows. I have XP so picked that one up

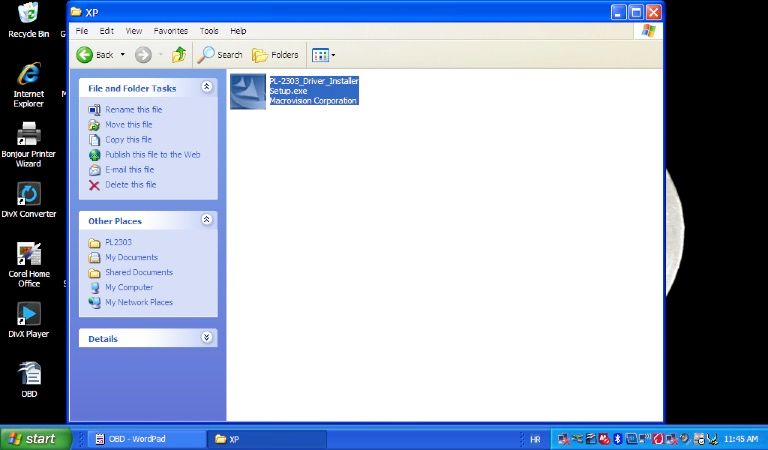

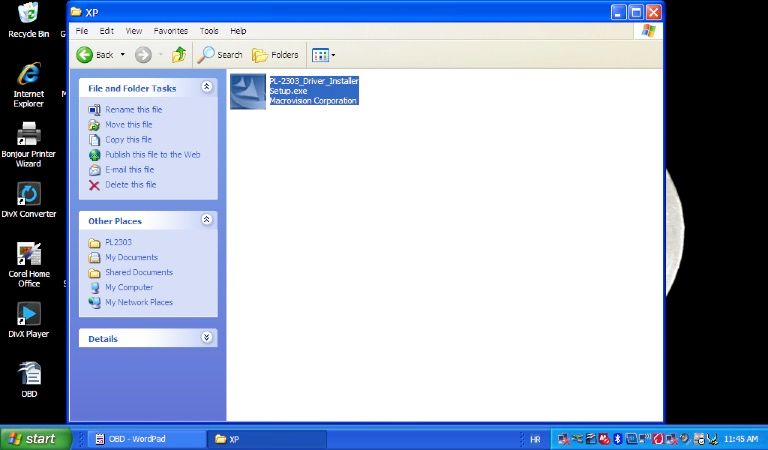

After that just click on the icon inside and let it do the work. When finished everything should be setup and working

Download the forscan here: http://www.forscan.org" onclick="window.open(this.href);return false;

It is free. Unbelieveable it is free, as it is incredible piece of kit!

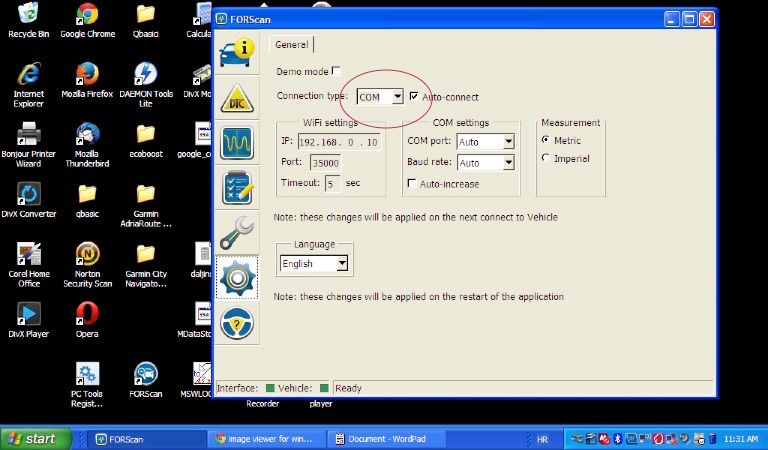

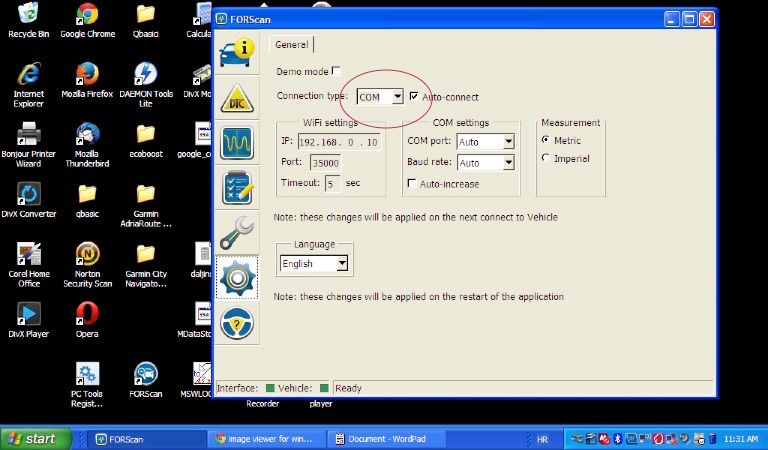

Go inside to setup and set the connection to COM. The OBD scanner should be now connected to the computer

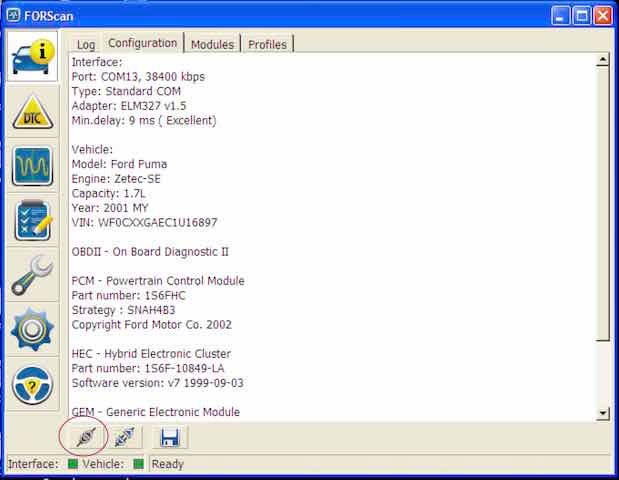

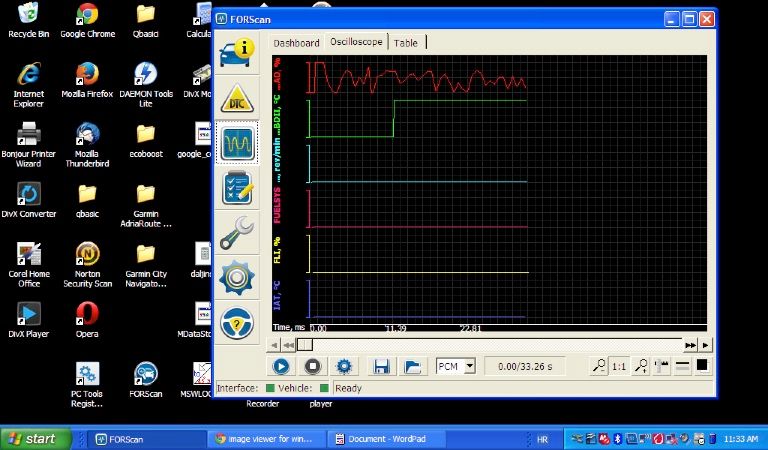

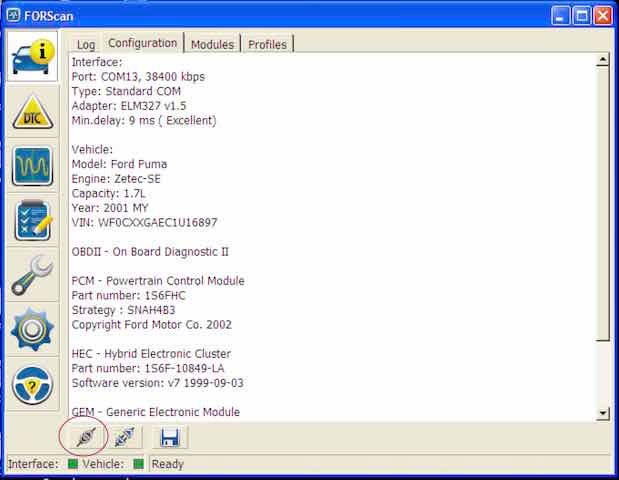

Program will find your scanner and after connection to the car and turning the key to either II position, or starting the engine the LED will turn to green. You just click to this simbol to connect it to the car and it will scan it and show you something like this

After that it is just a matter of trying different things and discovering what you wanted to know with the software….

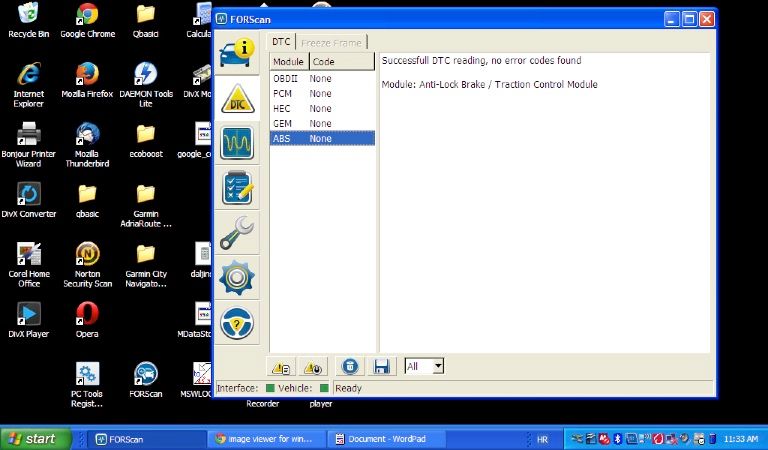

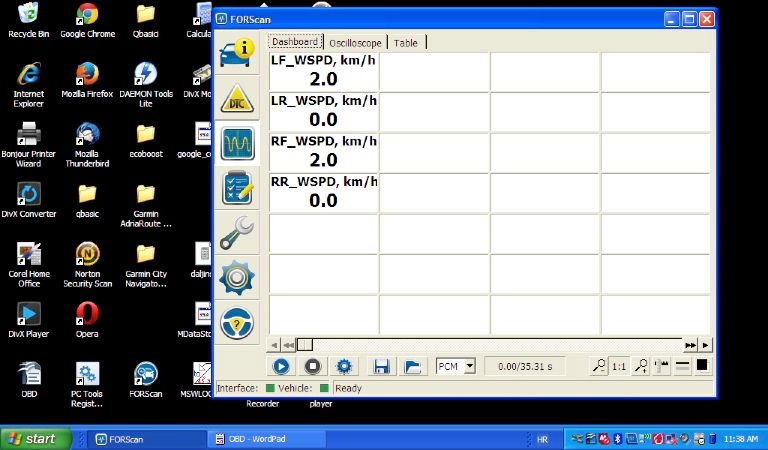

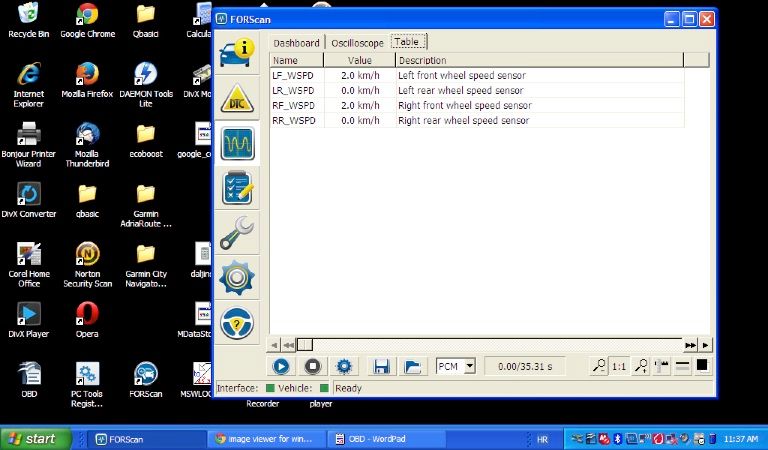

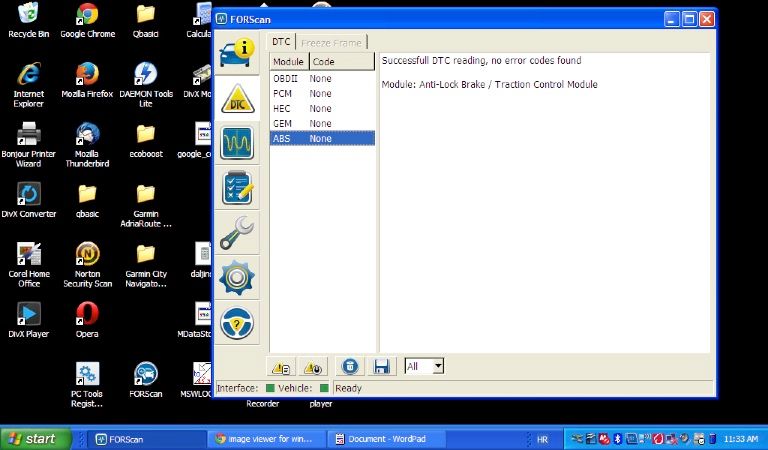

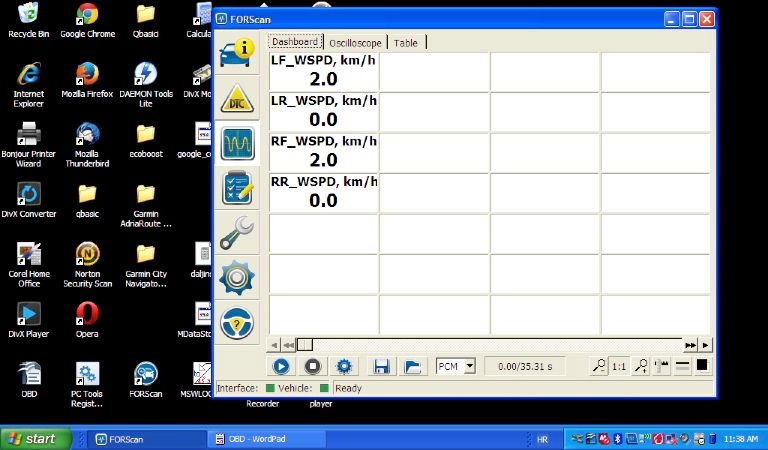

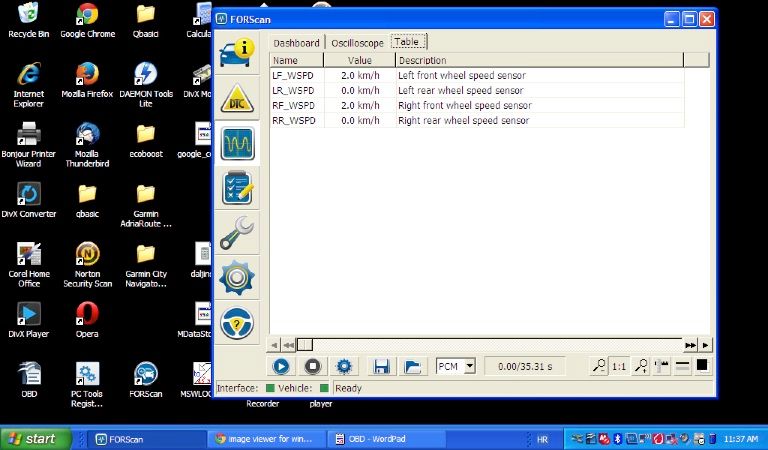

The ABS that is your focal point and live scanning of speed of each wheel that will tell you where is your problem

Or you can look at each moment

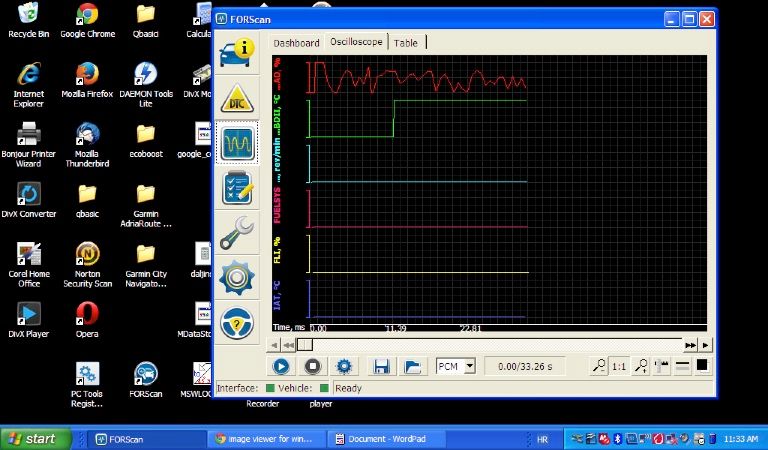

You can monitor other data as well and record it for later analysis or future reference…

Hope that helps! It is not black art, just another version of a spanner!